MyControl

Propuesta

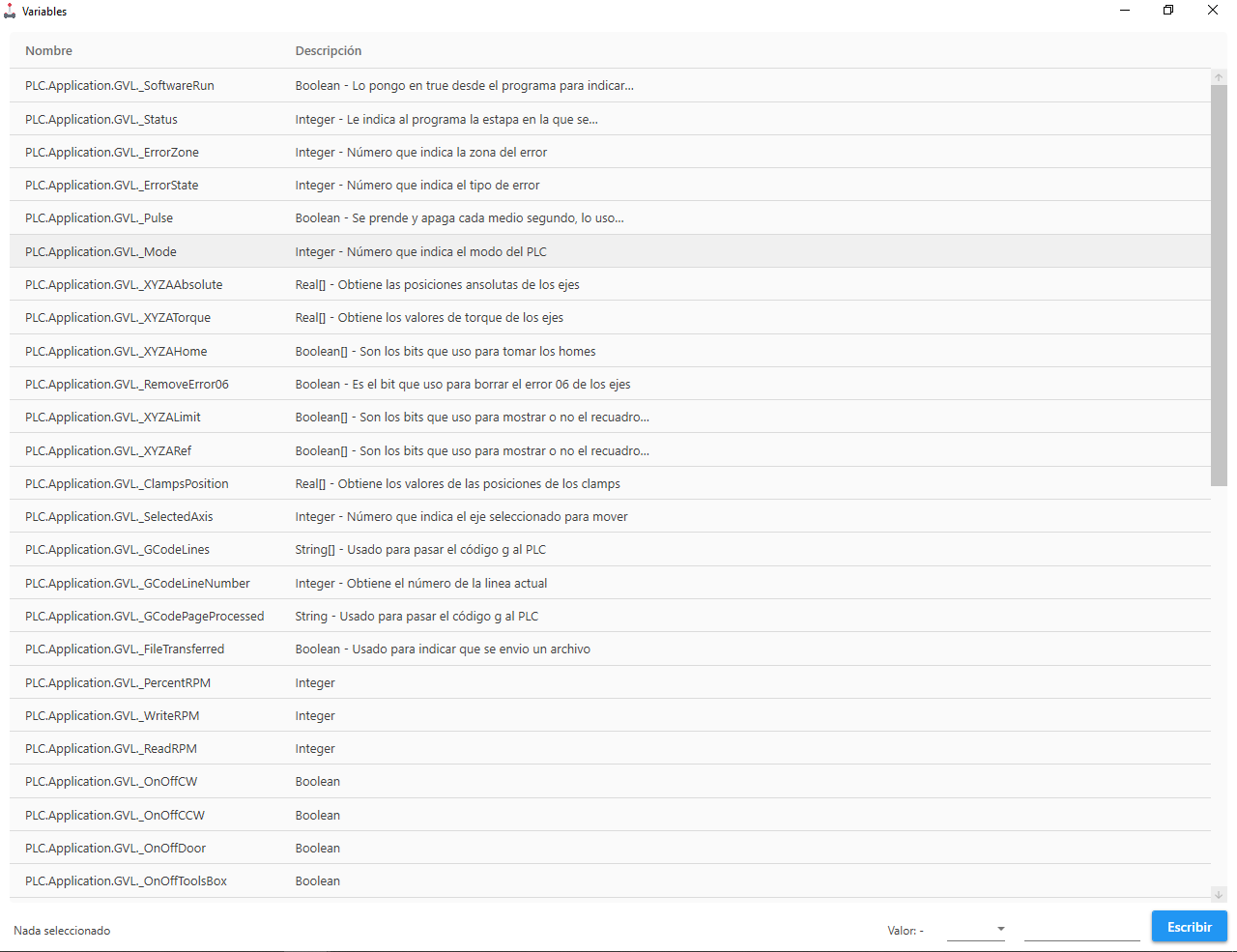

MyControl es un programa que lee código g, lo interpreta y genera los cambios necesarios para ser enviado a una máquina. A través de protocolos de comunicación como OPC o Modbus nos conectamos a los PLC para poder enviar información, recibir información, y generar cambios en variables para un correcto funcionamiento.

Algunas pantallas

Automático

En esta pantalla se puede observar el código g leído por el programa, a su vez se pueden ver las posiciones actuales y las velocidades de los ejes y se pueden cambiar de manera porcentual el avance y las rpm.

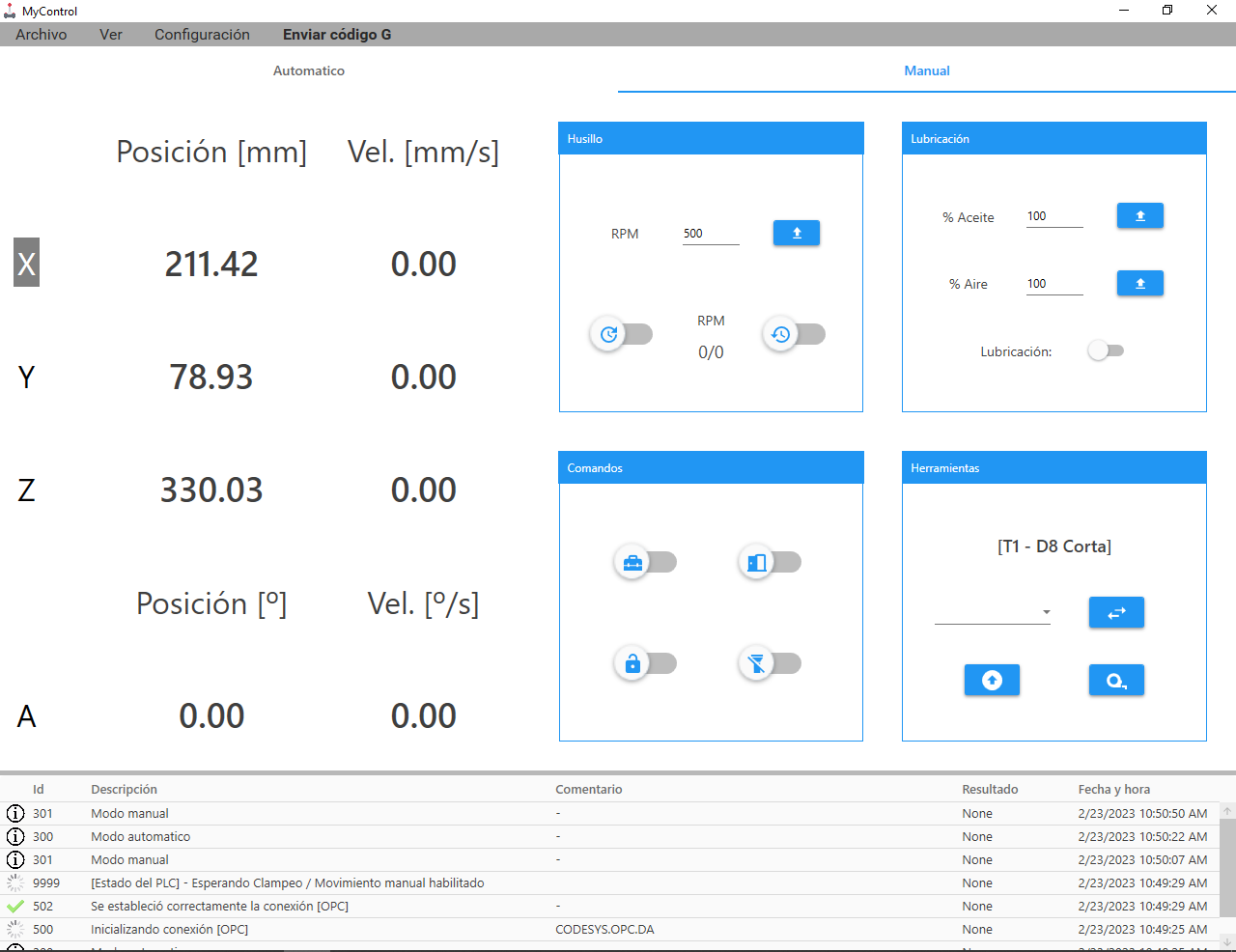

Manual

Al igual que la pantalla de automático, permite ver las posiciones actuales y las velocidades de los ejes, también permite ejecutar movimientos y acciones comandadas por el operario, como abrir el cajon de las herramientas, prender una luz, cambiar una herramienta, encender el husillo, etc. Nota: cada uno de estos botónes tiene tooltips que ayudan para entender que funcion realiza el mismo.

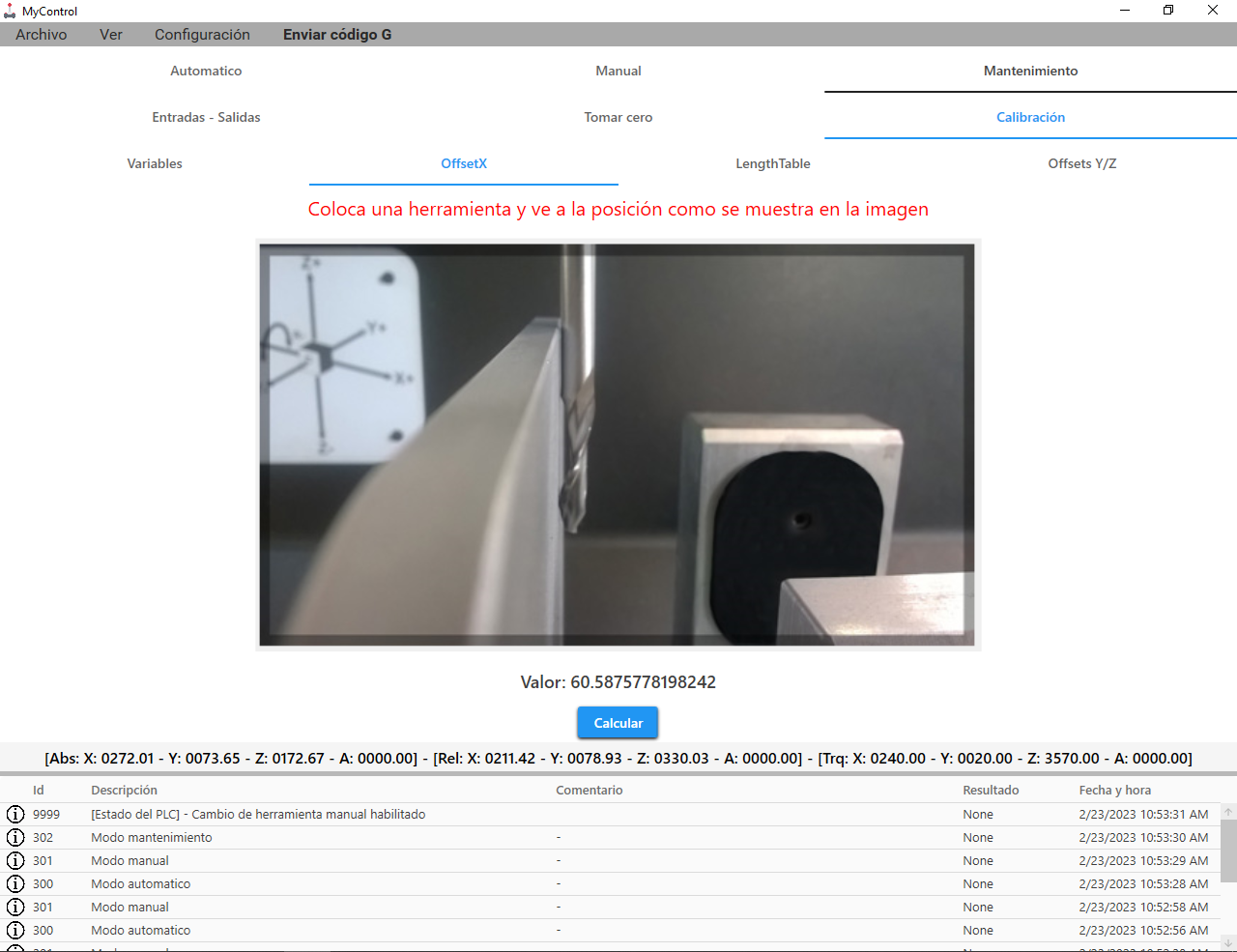

Calibración

Facilitamos la calibración de la máquina con imagenes, acompañadas de explicaciones, las cuales sirve para idicar a donde mover determinados ejes, para que con la posición actual el programa calcule los parametros.

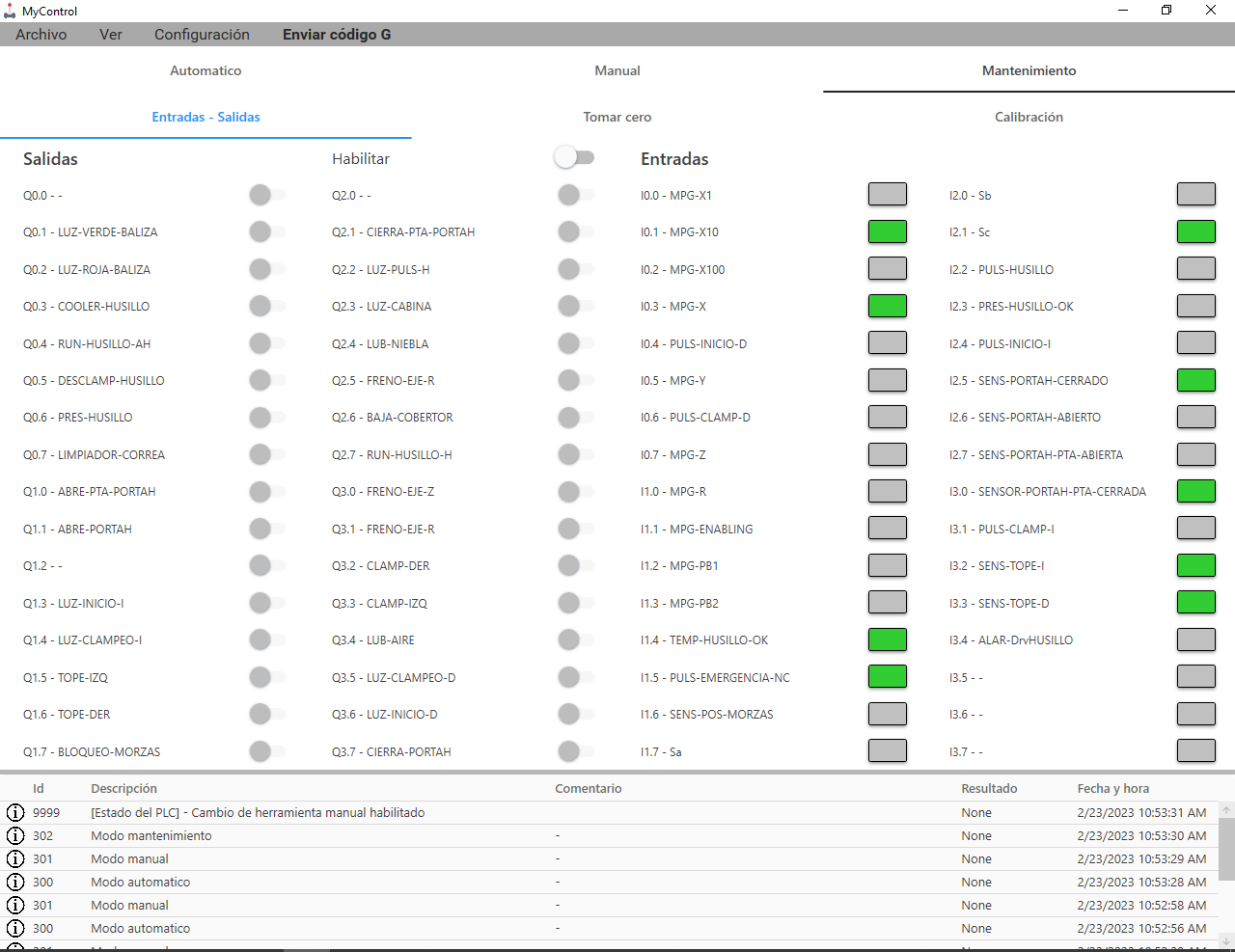

Entradas y salidas

Generamos una ventana en la cual podemos ver las entradas y con un botón de encendido tomamos el control de las salidas, esto sirve principalmente para probar que todo funciona correctamente.

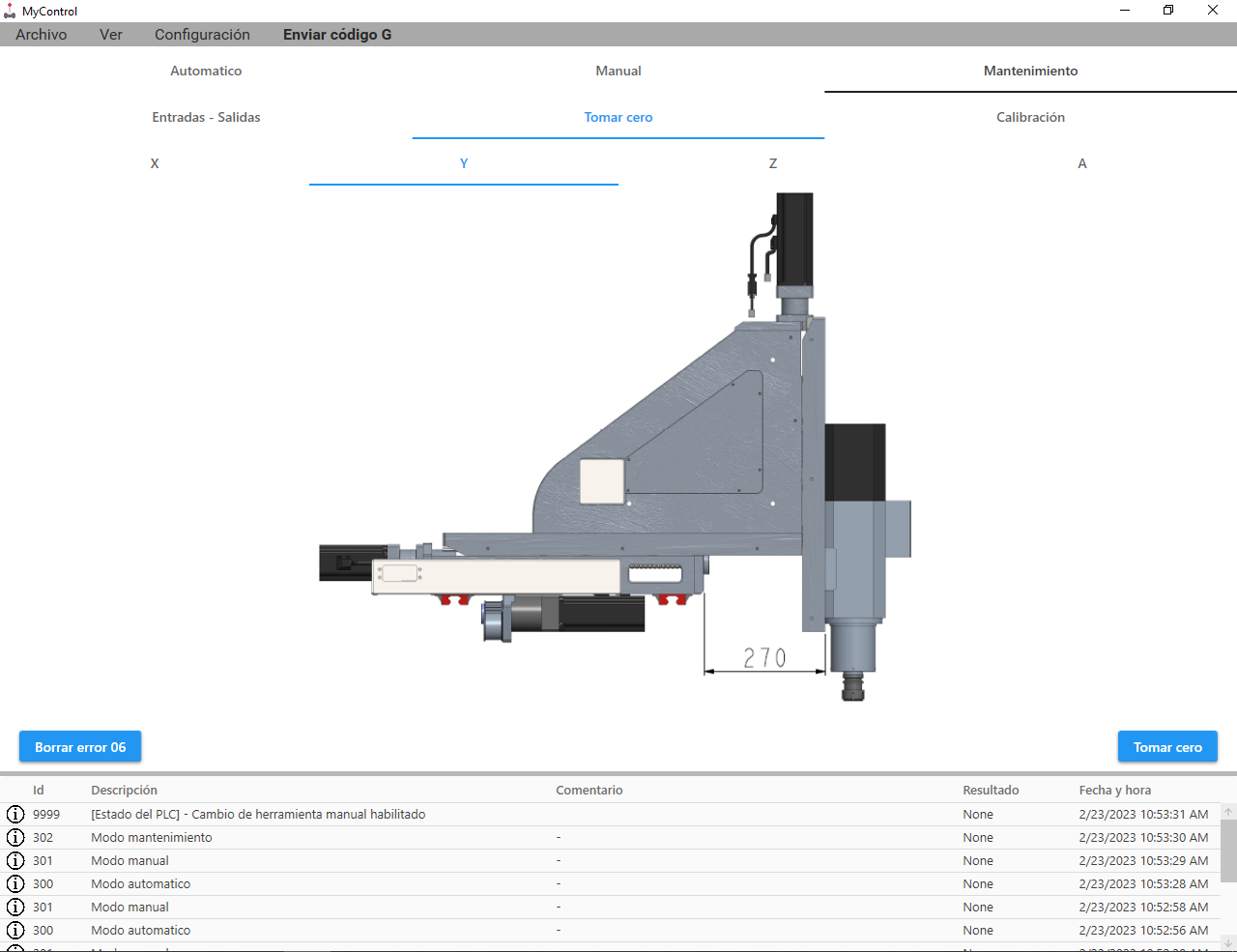

Tomar cero

Facilitamos la puesta a cero de los ejes con diagramas que muestran las posiciones correspondientes a cada eje. Simplemente muévalo a esa posición y presione un botón para completar la posición inicial.

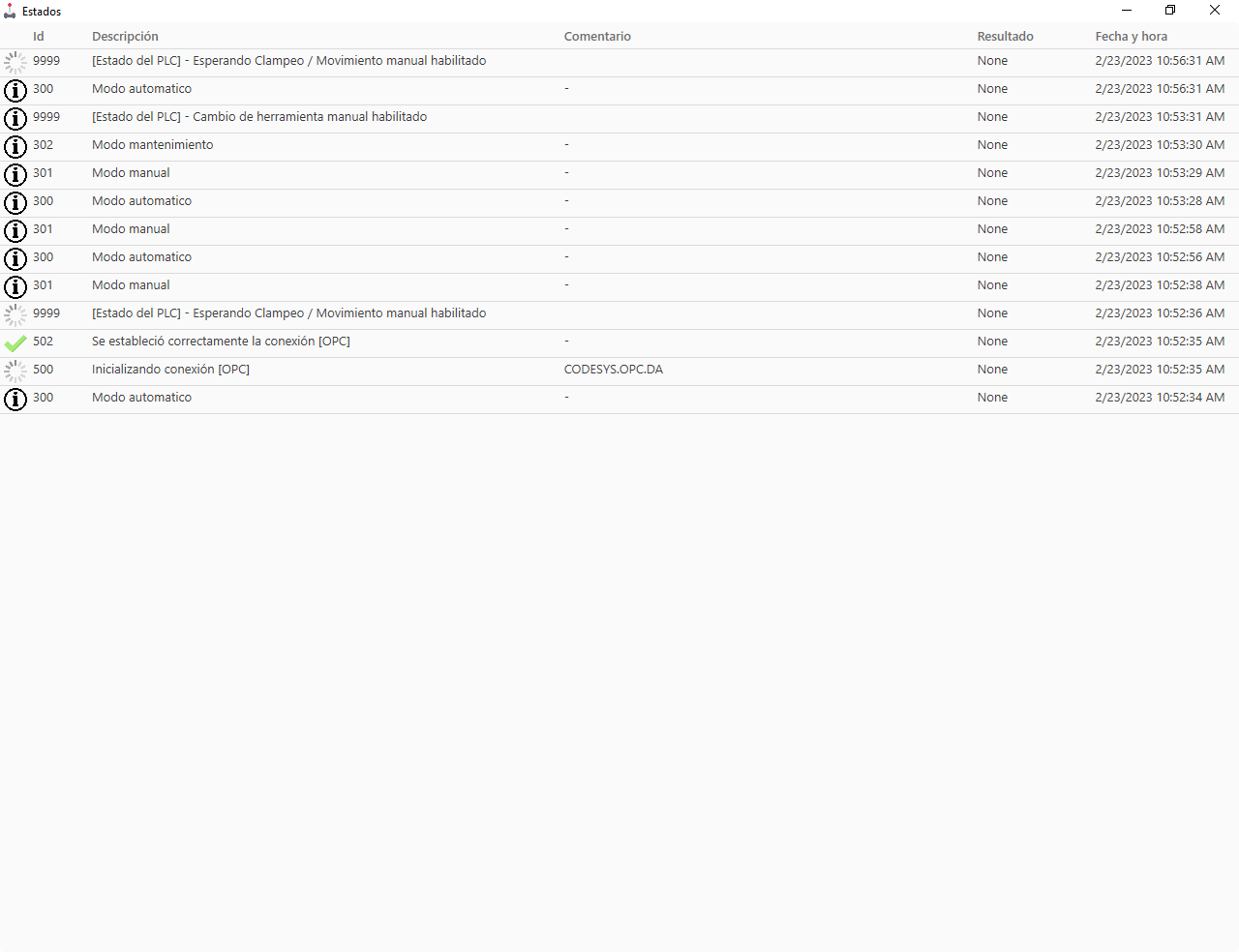

Estados

En la parte inferior del programa podemos encontrar una barra de estados en la cual se mostraran los distintos estados del programa, o del PLC. Esta barra es pequeña por lo que decidimos generar una ventana para monitorear todo los estados por los que paso el programa desde que lo iniciaste: Allí se pueden leer y observar los errores con mayor detalle.

Forma de trabajo

Entendemos que cada tipo de máquina y mercado donde se aplica este programa es diferente. Por lo tanto, nos adaptamos a sus necesidades de la mejor manera posible, modificando el software para que se adapte correctamente. Si tiene alguna pregunta o desea saber si el software se adapta a su caso particular, puede consultarlo en el siguiente enlace: contacto